Life

A Robot Built An Ikea Chair In 20 Minutes & It’s Actually A Big Scientific Leap Forward

Look, robots and artificial intelligence (AI) get a bad rap, from all the fuss around them taking over our jobs, to rising up and overthrowing humans. But some folks may rethink their positions after finding out that ~science~ has gifted us with robots that can put together Ikea furniture.

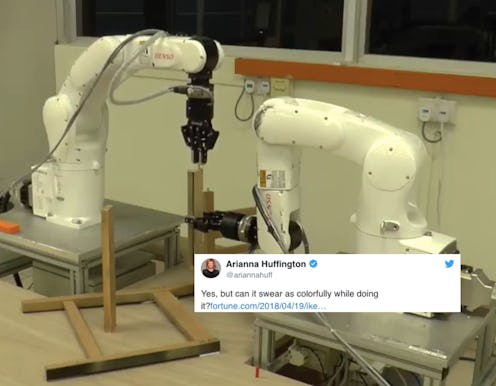

A report published April 18 in Science Robotics chronicles researchers' successful attempts to build a robot (using "entirely off-the-shelf parts," by the way — "two industrial robot arms with force sensors and a 3-D camera," according to Wired) that can take care of one of the actual most annoying things on the planet: The need to put together your new flatpack yourself.

Researchers reported that the robot arms put together a Stefan chair from Ikea in 20 minutes. Just 20 minutes. Imagine a future where you bring your flatpack home and spend 20 minutes having Netflix beamed directly into your eyeballs, and then simply turn around and see that your furniture is completed. No muss, no fuss, no misery naps or resorting to paying some guy on Craigslist to come build the thing for you.

According to Wired, this is a big deal not just because it could chuck approximately 80 percent of the daily human struggle out the window, but because robots usually "struggle mightily to manipulate objects in a world built for human hands." So the fact that researchers managed to put together a robot that can follow Ikea's instructions and manipulate the various screws and pegs signifies a real push forward in robot dexterity.

If you're wondering how the robot arms were able to follow instructions when everyone knows that is notoriously impossible, well, the researchers helped them get started. According to Wired, researchers created a code version of the typical quote-unquote super-simple illustrated assembly instructions. "Then they place[d] the pieces in a random pattern [in] front of the robots, which eyeball the wood with the 3-D camera." It was the robot's job to take the list of instructions the researchers gave them and match them to the randomized parts.

Here's how that process works: "What the robot does is to first figure out where exactly is the original position of the frame," Quang-Cuong Pham, an engineer out of Nanyang Technological University in Singapore, told Wired. Once the robot figures out the original position, it "calculates the motion of the two arms automatically to go and grasp it and transport it."

Wired explained that the two arms have to coordinate motions, and because the camera "only has an accuracy of a few millimeters," the robots will have to make up for that shortfall sometimes by feeling around for where to insert pegs or slide pieces together. For example, if the robot is trying to insert a peg, it will make "swirling motions around the hole, and when it feels the force pattern change, it knows the peg has dropped in slightly, then will apply more force to fully insert the thing."

That swirling pattern is coded into the robot, but Pham told Wired while it's extremely useful at helping the robot put together items with greater-than-human speed and accuracy, it can also cause issues. If the robot misses the hole with the peg, but goes over the side of the piece, it will "go and insert [it] in the void," Pham told Wired, because it would still detect a change in force.

Another issue the robot can run into is a sort of, er, disagreement in the ranks, shall we say. As in, the two arms can end up duking it out if there's been a miscalculation. "If there is a small error, for example in the modeling of the object, then the arms would fight each other, pulling this direction and the other pulling in another direction," Pham told Wired. "If that happens the robot will break the object."

Pham added that they've compensated for a problem like that by adding force sensors, which can sense when the force on the object is too great and tell the robot to go gently into that good Ikea.

Unfortunately, home robots that can do all our Ikea assemblage aren't exactly going to be coming out tomorrow. Ken Goldberg, who works in robotic manipulation at UC Berkeley, told Wired that, "This is a nice result," but, "[t]he big challenge is to replace such carefully engineered special purpose programming with new approaches that could learn from demonstrations and/or self-learn to perform tasks like this."

Pham told Wired intelligence like that is in the pipeline. "The final level is we show the robot an image of the assembled chair and then it has to figure it out," he said. "But I would envision this last step in the next probably five or six years."

So, no instant solution for your Ikea assembly woes. But next time you're putting together your new desk or chair or bookshelf and you maybe kind of wish robots had already taken over the world so you just don't have to do this anymore, remember one day, in a glorious future, you may never have to lay your hands on another wooden peg again.